The use of terrestrial LiDAR to improve safety in mines

There’s simply no escaping the many use cases of LiDAR (Light Detection and Ranging) across a broad range of industries. LiDAR is no stranger to the mining industry, helping to monitor inventories, mapping landscapes, providing accurate pit models, and identifying objects or mining features, among many other things.

However, more importantly, LiDAR is proving to be a fundamental technology that can reduce human and environmental risks in mines across Australia. Through its ability to detect, identify and evaluate potential hazards, LiDAR is making mining operations safer, through an ever-growing list of applications.

What is terrestrial LiDAR?

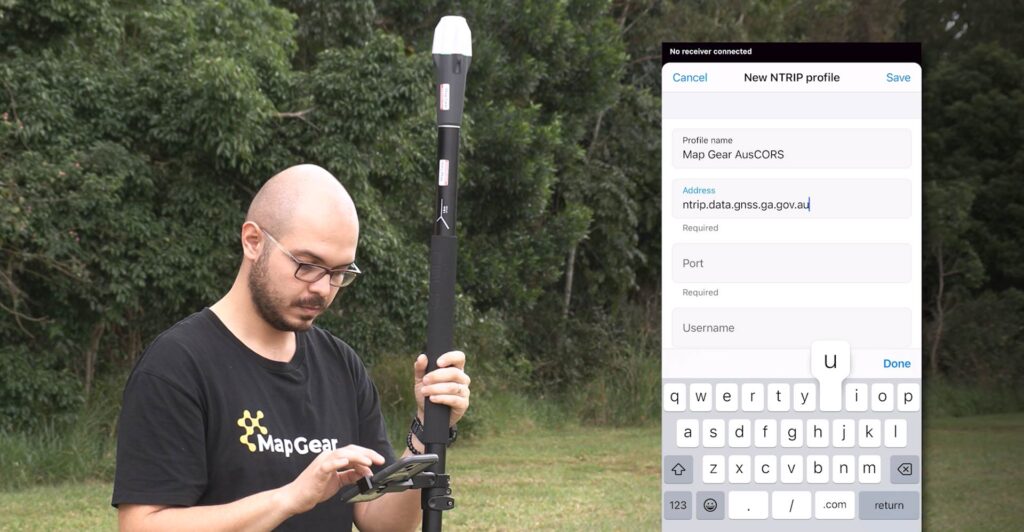

LiDAR Radar defines terrestrial LiDAR as a system that “can be either mounted on a moving vehicle or implanted at a static location. Either way, terrestrial LiDAR data is beneficial for applications that require a detailed survey of the ground or “a closer look” at objects”.

Terrestrial LiDAR is further classified as either Mobile or Static, with mobile LiDAR applications generally placed on a moving vehicle, and static applications fixed to one point.

We’ve put together some ways we’ve seen our LiDAR solutions implemented across Australian mine sites to improve safety.

Void monitoring

The Void Monitor system assesses ground conditions at an unloading location such as a vertical void. By continuously monitoring the status of the edge to ensure it is safe for a vehicle to unload and reporting to an indication point using a traffic light system, vehicle operators are made aware of potential hazards before they proceed to tip.

The red light displays when there is an over break (collapse of rock) and the area is unsafe. An amber light is shown when the monitor detects that the area has filled to its capacity, notifying the driver not to proceed. And finally, the green light notifies the driver that the edge is structurally sound, and the driver can proceed to unload.

3D visualisation

Reducing the need for human intervention is a primary method in helping mines operate safely. Whether this is in a hard-to-reach location, hazardous area, or dangerous vertical shafts, 3D visualisation can help inspect and monitor these areas by having your team enter potentially unsafe areas.

Carryback and hang-up mitigation

Using static terrestrial LiDAR to monitor hopper bins not only helps improve transport efficiency but also reduces the chances of dangerous derailments caused by the unplanned discharge of remnant materials after unloading.

By detecting that the hopper bins have been emptied correctly, LiDAR technology helps avoid incomplete dumping and the risk of materials potentially falling on tracks or pathways.

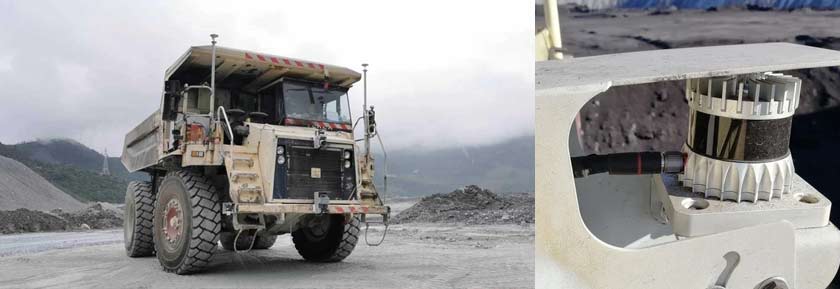

Obstacle detection and avoidance

With many vehicles moving materials throughout the site, and operators working long hours, obstacles can present a risk to your mining operations. Fitting your fleet with sensors to provide a 3D model of the world around it, as moves through the site, ensures you and your team react safely to potential hazards and avoid accidents.

At its simplest, this can be used to notify the driver of a hazardous object on the horizon, or for more sophisticated applications it can be used to automatically stop or divert the vehicle.

Automated volume estimation of haul truck loads

By assessing the payload volume, mass, and distribution of materials, mine operators can improve the load quality and reduce damage to the truck. More importantly, load volume estimation can help avoid overloading or depositing a payload in a manner that can injure the driver.

Using LiDAR technology, the in-situ volume of the load is measured and ensures the load bed is maximised without overloading the vehicle.

Ouster’s high-performance LiDAR solutions

If you’re seeking to improve safety within our mine operations, there are currently three Ouster LiDAR sensors available in our online store. The OS0 provides an ultra-wide field of view, which is perfect for situational awareness in all types of weather conditions. The OS1 enables 3D sensing and is ideal for removing blind spots. Finally, the OS2 provides long-range, high-resolution 3D sensing, ideal for high-altitude drones.